Our Comparison of cost, material and time usage in FDM and SLS PDFs

3D printing and traditional manufacturing processes

The Greatest Guide To The Difference Between 3D Printing and Rapid Prototyping

Biocompatibility is very important for surgical instruments and lots of medical gadgets. Prototype designs assist design teams make more educated decisions by obtaining indispensable information from the performance of, and the response to, those models. The more data that is gathered at this phase of the item advancement cycle, the better the opportunities of avoiding prospective item or producing concerns down the roadway.

What is the finest way to get a model made? The response depends upon where you are in your process and what you are trying to accomplish. Early in the design process, when the concepts are streaming easily, idea designs are valuable. As the design progresses, a model that has the size, surface, color, shape, strength, resilience, and material attributes of the desired final product ends up being increasingly essential.

Fully inkjet-printed microfluidics: a solution to low-cost rapid three-dimensional microfluidics fabrication with numerous electrical and sensing applications - Scientific Reports

In order to a lot of efficiently validate your style, pay very close attention to these 3 key components of your design: functionality, manufacturability, and practicality. If your model can consistently represent the qualities of the end-product, it is by meaning. These requirements often consist of such things as product homes (e. g., flame resistance), dimensional precision for fit-up with mating parts, and cosmetic surface area finishes for look.

These requirements include the ability to preserve the performance of the style as explained above, keep the piece-part cost below the needed level, and support the production schedule. No matter how great a design is, it will go no place if it can't be manufactured. Make Check it Out takes this into consideration.

How Rapid Prototyping and 3D Printing - MFG Construction and can Save You Time, Stress, and Money.

Models are the just real method to verify the of the style in this sense. If your style can also pass the challenges associated with market trials (e. g., trade convention screens, use testing) and regulatory testing (e. g., FDA screening of medical devices), you're well on your way to an effective item launch.

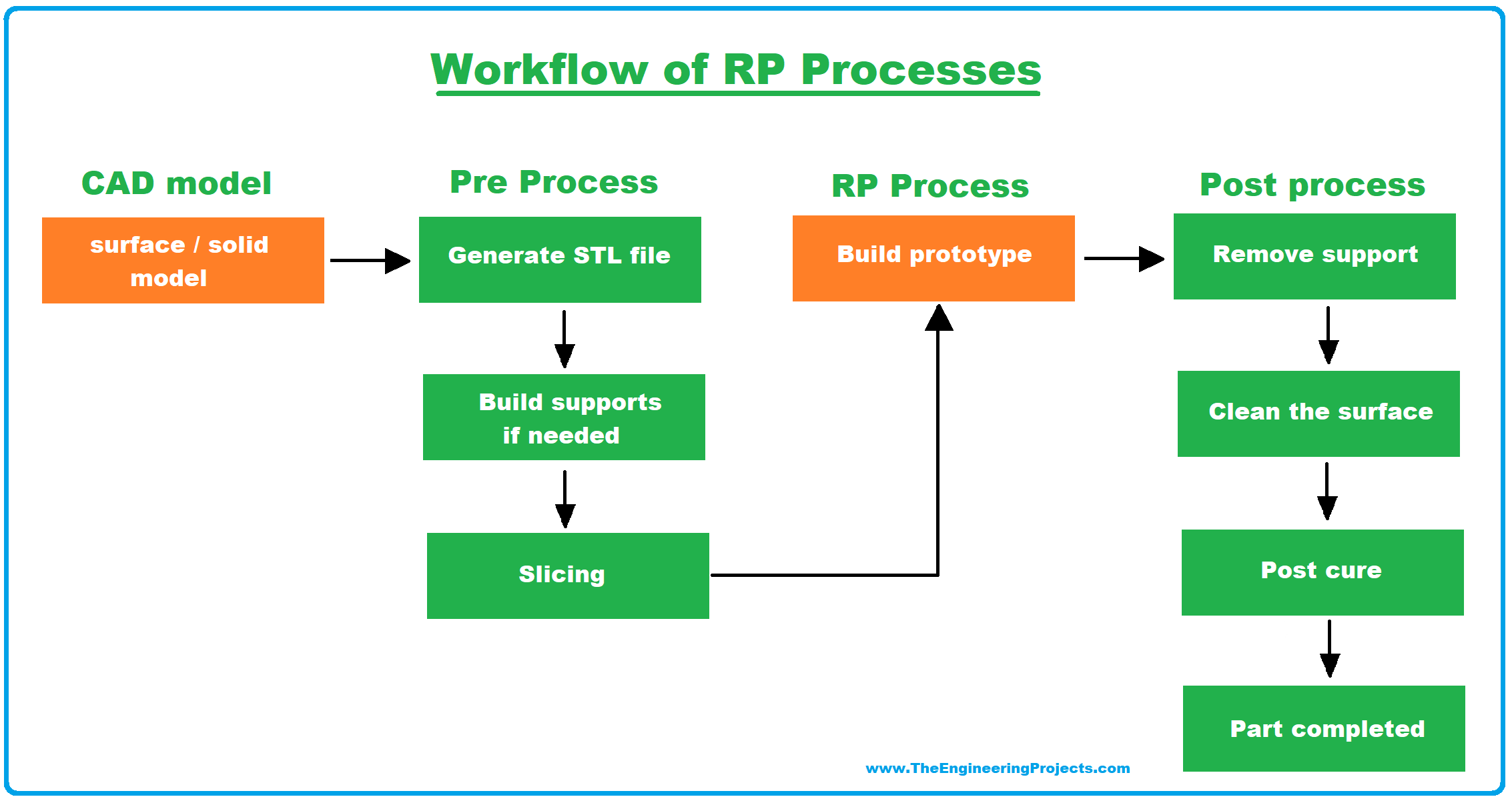

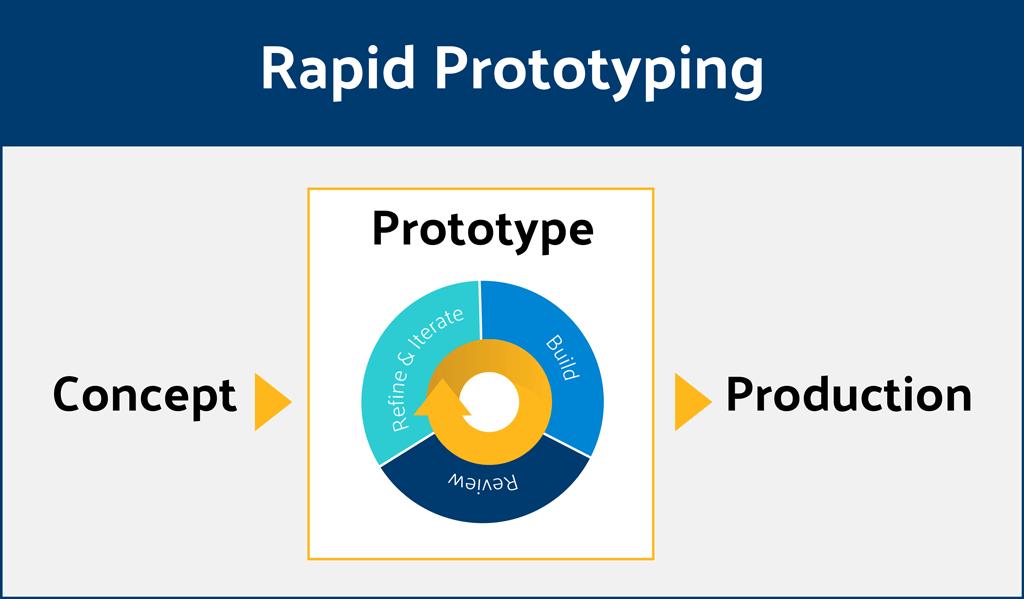

December 1, 2020 What is Rapid Prototyping? Quick prototyping is a series of methods that are utilized to rapidly fabricate a scale design of a physical part or assembly utilizing a 3D computer-aided design (CAD). The part that is created is then put together through 3D printing. At Southern Model, we provide the following 3D printing services: When it pertains to three-dimensional architectural models, there are a couple of types that are utilized.